Various types and specifications of devices under test

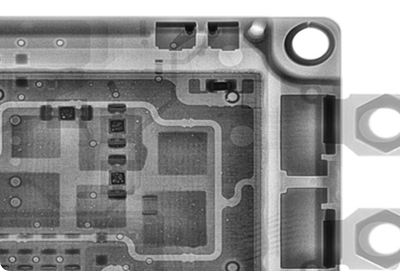

2.5D/3D/online equipment is not yet popular

Fierce price competition for 2D equipment

High technical barriers for 2.5D/3D/online equipment

Provides a cost-effective 49.5um version to meet stringent cost requirements for offline equipment

Offers a balanced performance version, considering large field of view and image quality, adapting to diverse scene requirements

Excellent visual effects enhanced by outstanding image algorithm

High-speed CMOS detector meets online CL requirements

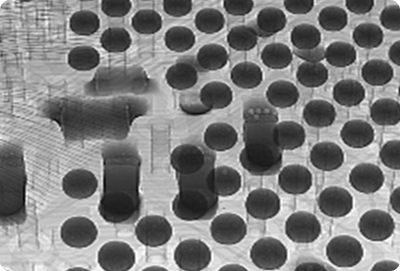

Micron-level small size s under test

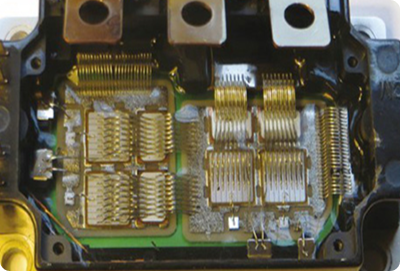

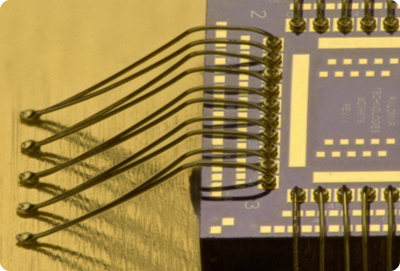

Difficulties in detecting bonding line solder joint defects

Low detection efficiency and high costs

Higher sensitivity allows observation of complex scenes like inside solder balls

Multiple resolution specifications, ranging from the most cost-effective solution to the most advanced option, optimize the overall cost of the detection system

Excellent visual effects enhanced by outstanding image algorithm

Various tray types

Wide range of measured s

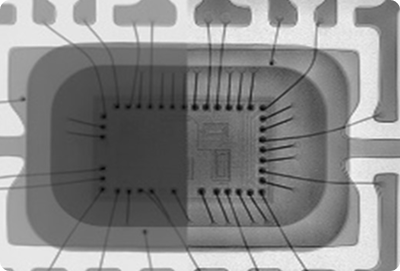

Difficulty in detecting very small components

Compatibility and scalability of recognition algorithms

Provides ultra-large field of view detectors, enhancing detection efficiency for general machines and optimizing costs

AED function improving efficiency and convenience

Offers high-resolution detectors suitable for 008004 and smaller trays

Thick l shell increase difficulty

Different types of shell and bonding line materials

Low inspection efficiency

Different types of shell and bonding line materials

Excellent image algorithm greatly enhances visual effects